loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

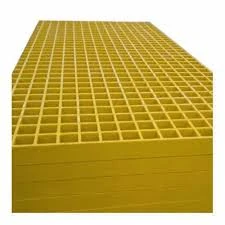

heavy duty bar grating

The Importance of Heavy Duty Bar Grating in Industrial Applications

Heavy duty bar grating is a crucial component in various industrial settings, providing sturdy support and safety for both personnel and equipment. Made from materials such as steel, aluminum, or fiberglass, this type of grating is designed to bear substantial loads while allowing for efficient drainage and airflow. Its applications extend across multiple industries, highlighting its versatility and significance in ensuring operational efficiency.

What is Heavy Duty Bar Grating?

Heavy duty bar grating consists of a series of parallel bars that are welded or riveted together, creating a grid-like structure. The bars are typically spaced to allow for the passage of light, air, and fluids while providing a solid surface for walking, driving, or placing heavy equipment. The design of this grating takes into account factors such as load-bearing capacity, slip resistance, and durability, making it suitable for both indoor and outdoor applications.

Advantages of Heavy Duty Bar Grating

1. Load-Bearing Capacity One of the primary benefits of heavy duty bar grating is its ability to withstand significant weight without compromising structural integrity. This makes it ideal for use in high-traffic areas, such as factories, warehouses, and loading docks, where heavy machinery and equipment are frequently moved.

2. Safety The slip-resistant surface of heavy duty bar grating enhances safety for workers. It minimizes the risk of slips and falls, which are common in industrial environments, especially when floors may become wet or slippery. Additionally, the open design allows for quick drainage of liquids, reducing the likelihood of pooling and further decreasing slip hazards.

3. Durability Constructed from robust materials, heavy duty bar grating is engineered to withstand harsh conditions, including exposure to chemicals, extreme temperatures, and heavy foot traffic. This longevity translates into cost savings for businesses, as the need for frequent replacements or repairs is greatly diminished.

4. Versatility Heavy duty bar grating can be custom-fabricated to meet specific requirements, including varying sizes, materials, and load capacities. It can be used in a diverse range of applications, from flooring and walkways to platforms and drainage covers. Industries such as manufacturing, oil and gas, water treatment, and construction all benefit from the adaptability of this grating.

heavy duty bar grating

5. Easy Maintenance Maintenance of heavy duty bar grating is generally straightforward. The open design allows for easy cleaning and inspection, ensuring that any debris or buildup can be quickly addressed. This is particularly important in environments where hygiene is crucial, such as in food processing facilities.

Applications of Heavy Duty Bar Grating

Heavy duty bar grating finds application in numerous settings

- Industrial Flooring It serves as a durable flooring solution in factories and warehouses, allowing for the safe movement of heavy equipment while maintaining an efficient workflow.

- Walkways and Platforms Bar grating is commonly used for elevated walkways and platforms, providing safe passage and access to machinery and operations in facilities that require both safety and strength.

- Drainage Systems The open grid design of heavy duty bar grating facilitates effective drainage in areas prone to water accumulation, such as outdoor loading docks, industrial wash bays, and waste treatment facilities.

- Event Venues In temporary structures such as concert stages or exhibition flooring, heavy duty bar grating provides a strong, safe surface that can support heavy equipment and large crowds.

Conclusion

In conclusion, heavy duty bar grating is an indispensable element of many industrial operations. Its blend of strength, safety, and versatility makes it an ideal choice for a wide range of applications. Businesses that prioritize the integration of heavy duty bar grating into their infrastructure can expect improvements in worker safety, operational efficiency, and overall durability. As industries continue to evolve, the need for robust, reliable materials like heavy duty bar grating will remain paramount, supporting the demands of modern manufacturing and construction. By investing in quality bar grating solutions, companies not only enhance their operational capabilities but also contribute to a safer working environment for their employees.

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024