loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Industrial Water Filtration Solutions for Enhanced Efficiency and Sustainability in Processes

Industrial Water Filter Systems Ensuring Clean Water for Industrial Processes

In the modern industrial landscape, the significance of clean water cannot be overstated. Water plays a pivotal role in various manufacturing processes, cooling systems, and as a solvent in chemical reactions. Consequently, the treatment and filtration of water are critical for maintaining operational efficiency, ensuring product quality, and complying with environmental regulations. This brings us to the concept of industrial water filter systems, which are designed to meet the unique water purification needs of different industries.

Understanding Industrial Water Filtration

Industrial water filter systems are sophisticated solutions aimed at removing impurities from water before it is used in production processes. These systems address a variety of contaminants, including sediments, bacteria, heavy metals, and chemicals, ensuring that the water used is of the highest quality. The filtration process typically involves a series of steps, utilizing different technologies such as sedimentation, microfiltration, ultrafiltration, reverse osmosis, and carbon filtration.

1. Sedimentation This is the initial stage where larger particles settle at the bottom of a tank due to gravity. This simple yet effective method helps in reducing the load on subsequent filtration processes.

2. Microfiltration This step employs membranes with pore sizes typically ranging from 0.1 to 10 micrometers. It effectively removes bacteria, suspended solids, and some larger viruses, making it ideal for pre-treatment applications.

3. Ultrafiltration Here, a membrane with smaller pore sizes is used to separate smaller particles and macromolecules, including proteins and polysaccharides, which are often found in industrial wastewater.

4. Reverse Osmosis (RO) Reverse osmosis is used to remove dissolved salts and other impurities from water by applying pressure to force water through a semi-permeable membrane. This process is crucial for industries that require extremely pure water, such as pharmaceuticals and electronics manufacturing.

5. Carbon Filtration This method utilizes activated carbon to remove chlorine, volatile organic compounds (VOCs), and odorous substances, improving the taste and odor of the water.

Benefits of Industrial Water Filter Systems

Implementing an industrial water filter system offers numerous benefits, including

industrial water filter system

- Enhanced Water Quality Clean water is essential for consistent product quality and safety. Filtration systems ensure that water used in various processes is free from harmful contaminants.

- Operational Efficiency When water is filtered and treated properly, it can improve the performance of machinery and reduce downtime caused by equipment failure due to water quality issues

.- Compliance with Regulations Many industries are subject to stringent environmental regulations regarding wastewater discharge. Effective filtration systems can help companies comply with these regulations, avoiding hefty fines and environmental damage.

- Cost Savings Investing in water filtration systems can lead to significant savings in water usage and treatment costs. By recycling and reusing water, industries can reduce their overall water footprint, contributing to sustainability goals.

- Improved Health and Safety Clean water reduces the risk of health issues related to contaminated water sources, ensuring a safer workplace for employees.

Choosing the Right Water Filter System

Selecting the appropriate industrial water filter system depends on several factors, including the type of contaminants present, the volume of water required, and the specific needs of the industry. It is crucial to conduct a thorough analysis of water quality before implementing a filtration solution.

Companies often work with water treatment specialists to identify the most effective technologies and design systems that cater to their particular requirements. Customization is key, as one-size-fits-all solutions may not address the unique challenges faced by different industries.

Conclusion

As industries continue to evolve, the importance of industrial water filter systems becomes increasingly evident. These systems not only ensure the availability of clean water for various applications but also promote environmental sustainability and regulatory compliance. Investments in advanced filtration technology can lead to remarkable improvements in product quality, operational efficiency, and cost-effectiveness. In an age where water scarcity and pollution are pressing global challenges, effective industrial water filtration stands out as a vital component in paving the way for a cleaner, more sustainable industrial future.

-

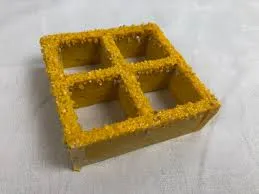

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024