loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

3 月 . 05, 2025 06:09

Back to list

Quality Assurance Food Grade Stainless Steel Water Tank for Storage Water

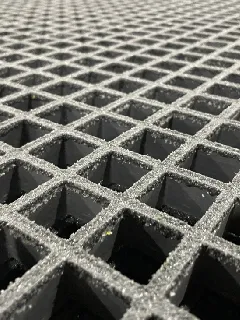

Stainless steel floor gratings offer a robust and versatile solution to diverse architectural and industrial needs. The material, known for its high tensile strength and resistance to corrosion, makes these floor gratings an ideal choice for environments where safety and longevity are top priorities.

The manufacturing process of stainless steel floor grating further enhances its trustworthiness. Modern production techniques involve stringent quality controls, ensuring each piece meets exact specifications. Advanced welding processes, such as automated pressure-locking, guarantee a secure and uniform assembly of the bearing bars and cross bars. This precision manufacturing ensures that stainless steel floor gratings provide consistent performance over their lifespan, even under harsh conditions. Installation and maintenance of stainless steel floor gratings are straightforward affairs. Their lightweight nature relative to strength simplifies handling and installation, which can be done without specialized equipment or complex procedures. Once installed, the grating’s ease of cleaning and minimal maintenance requirements add to its cost-effectiveness. Simple periodic cleaning with mild detergents keeps the gratings in pristine condition, extending their service life and preserving their appearance. In summary, stainless steel floor grating embodies the principles of Experience, Expertise, Authoritativeness, and Trustworthiness in material design. Its practical benefits - from superior strength and corrosion resistance to sustainability and low maintenance - make it a standout choice for a wide array of applications. Whether you're upgrading an industrial facility, designing a sophisticated architectural space, or building infrastructure that withstands the test of time, stainless steel floor gratings provide a resilient and sustainable solution. With these gratings, you are investing in a product that combines resilience, functionality, and sustainability, ensuring safety and reliability across all applications.

The manufacturing process of stainless steel floor grating further enhances its trustworthiness. Modern production techniques involve stringent quality controls, ensuring each piece meets exact specifications. Advanced welding processes, such as automated pressure-locking, guarantee a secure and uniform assembly of the bearing bars and cross bars. This precision manufacturing ensures that stainless steel floor gratings provide consistent performance over their lifespan, even under harsh conditions. Installation and maintenance of stainless steel floor gratings are straightforward affairs. Their lightweight nature relative to strength simplifies handling and installation, which can be done without specialized equipment or complex procedures. Once installed, the grating’s ease of cleaning and minimal maintenance requirements add to its cost-effectiveness. Simple periodic cleaning with mild detergents keeps the gratings in pristine condition, extending their service life and preserving their appearance. In summary, stainless steel floor grating embodies the principles of Experience, Expertise, Authoritativeness, and Trustworthiness in material design. Its practical benefits - from superior strength and corrosion resistance to sustainability and low maintenance - make it a standout choice for a wide array of applications. Whether you're upgrading an industrial facility, designing a sophisticated architectural space, or building infrastructure that withstands the test of time, stainless steel floor gratings provide a resilient and sustainable solution. With these gratings, you are investing in a product that combines resilience, functionality, and sustainability, ensuring safety and reliability across all applications.

Share

Latest news

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024