loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

1 月 . 26, 2025 06:23

Back to list

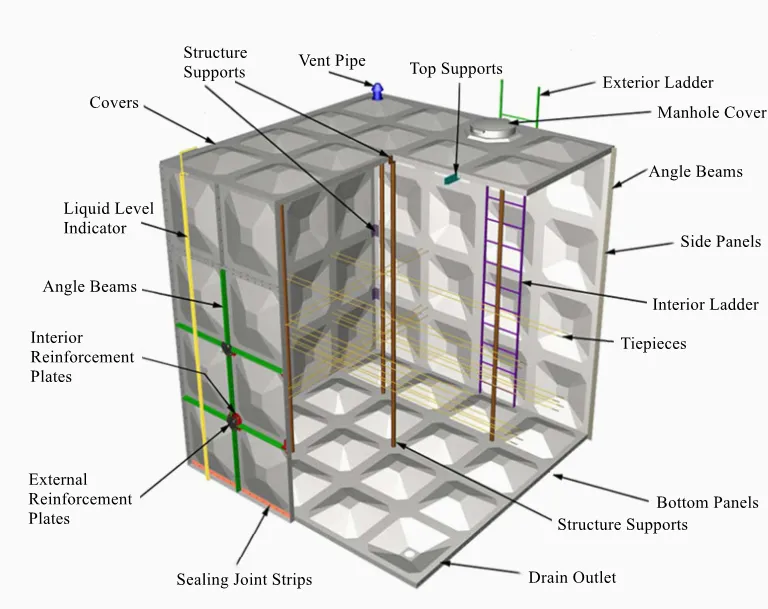

smc panel tank

The Starlite FRP tank stands as a paradigm of innovation and durability in the world of fluid storage solutions. Designed for industries that demand reliability under extreme conditions, this tank is not just a product but a testimony to advanced engineering. The fiber reinforced plastic (FRP) technology employed in the Starlite tank ensures exceptional resistance to corrosion, chemical degradation, and structural impacts.

Trustworthiness forms the bedrock of the Starlite FRP tank’s reputation. Each tank undergoes rigorous quality control checks before reaching the market. Suppliers and manufacturers are transparent about material sourcing and production methods, ensuring that every tank adheres to the highest standards of manufacturing excellence. This transparency builds trust, which is essential for long-term relationships with customers who depend on these tanks for vital operations. Real-world experience with the Starlite FRP tank further reinforces its value. Case studies reveal extended service life and enhanced performance metrics in various applications, such as storing reactive chemicals where lesser tanks might fail. Users recount that installation is straightforward, facilitated by detailed manuals and responsive support teams ready to assist with technical inquiries. In essence, the Starlite FRP tank does not just meet the needs of modern industries; it anticipates them. In conclusion, the Starlite FRP tank is a blend of advanced material science, practical design, and rigorous manufacturing standards. Its design and functionality embody a commitment to quality that industries can rely on. Choosing this tank means investing in a future-proof solution that delivers on promises of durability, safety, and efficiency. Those seeking a dependable storage solution will find the Starlite FRP tank to be an unparalleled choice, melding innovative technology with trusted performance.

Trustworthiness forms the bedrock of the Starlite FRP tank’s reputation. Each tank undergoes rigorous quality control checks before reaching the market. Suppliers and manufacturers are transparent about material sourcing and production methods, ensuring that every tank adheres to the highest standards of manufacturing excellence. This transparency builds trust, which is essential for long-term relationships with customers who depend on these tanks for vital operations. Real-world experience with the Starlite FRP tank further reinforces its value. Case studies reveal extended service life and enhanced performance metrics in various applications, such as storing reactive chemicals where lesser tanks might fail. Users recount that installation is straightforward, facilitated by detailed manuals and responsive support teams ready to assist with technical inquiries. In essence, the Starlite FRP tank does not just meet the needs of modern industries; it anticipates them. In conclusion, the Starlite FRP tank is a blend of advanced material science, practical design, and rigorous manufacturing standards. Its design and functionality embody a commitment to quality that industries can rely on. Choosing this tank means investing in a future-proof solution that delivers on promises of durability, safety, and efficiency. Those seeking a dependable storage solution will find the Starlite FRP tank to be an unparalleled choice, melding innovative technology with trusted performance.

Share

Latest news

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024