loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

2 月 . 04, 2025 03:15

Back to list

stainless steel water tank rectangular

Choosing the right steel CHS (Circular Hollow Section) sizes is a critical decision for construction professionals, engineers, and architects. With an evolving landscape of materials and design considerations, understanding how to select the appropriate sizes not only influences the structural integrity but also impacts financial and environmental aspects of a project.

Incorporating authoritative guidelines and codes is non-negotiable in steel CHS sizing. Adhering to national and international standards such as those from the American Institute of Steel Construction (AISC) or the International Organization for Standardization (ISO) helps ensure compliance with safety and quality requirements. Such standards play a pivotal role in assuring stakeholders of the viability and safety of structures using CHS steel, reinforcing the decision-making process with robust, evidence-based criteria. Trustworthiness in steel CHS sizing can be cultivated through transparency and rigor in decision processes. Stakeholders must be assured of the rational and empirical basis for choices made, particularly in scenarios involving budget constraints or innovative design demands. Clear documentation and peer-reviewed design verifications can significantly enhance trust, demonstrating that size selections are neither arbitrary nor superficial but based on precise calculations and proven methodologies. Moreover, factors like cost efficiency and environmental impacts cannot be overstated. Opting for CHS sizes that mitigate waste through precision and appropriateness not only benefits the project's bottom line but contributes to sustainable practices. The recycling potential of steel and its reduced environmental footprint further bolster its suitability from an ecological perspective. In summation, selecting the appropriate steel CHS sizes is a multilayered process driven by experience, expertise, authoritative standards, and trust. Professionals in the field must navigate the intersection of these elements with acumen and foresight. As projects scale new heights in complexity and ambition, the demand for well-informed CHS size decisions becomes paramount, underscoring the indispensable role of knowledgeable professionals in shaping the built environment to meet contemporary and future needs.

Incorporating authoritative guidelines and codes is non-negotiable in steel CHS sizing. Adhering to national and international standards such as those from the American Institute of Steel Construction (AISC) or the International Organization for Standardization (ISO) helps ensure compliance with safety and quality requirements. Such standards play a pivotal role in assuring stakeholders of the viability and safety of structures using CHS steel, reinforcing the decision-making process with robust, evidence-based criteria. Trustworthiness in steel CHS sizing can be cultivated through transparency and rigor in decision processes. Stakeholders must be assured of the rational and empirical basis for choices made, particularly in scenarios involving budget constraints or innovative design demands. Clear documentation and peer-reviewed design verifications can significantly enhance trust, demonstrating that size selections are neither arbitrary nor superficial but based on precise calculations and proven methodologies. Moreover, factors like cost efficiency and environmental impacts cannot be overstated. Opting for CHS sizes that mitigate waste through precision and appropriateness not only benefits the project's bottom line but contributes to sustainable practices. The recycling potential of steel and its reduced environmental footprint further bolster its suitability from an ecological perspective. In summation, selecting the appropriate steel CHS sizes is a multilayered process driven by experience, expertise, authoritative standards, and trust. Professionals in the field must navigate the intersection of these elements with acumen and foresight. As projects scale new heights in complexity and ambition, the demand for well-informed CHS size decisions becomes paramount, underscoring the indispensable role of knowledgeable professionals in shaping the built environment to meet contemporary and future needs.

Share

Next:

Latest news

-

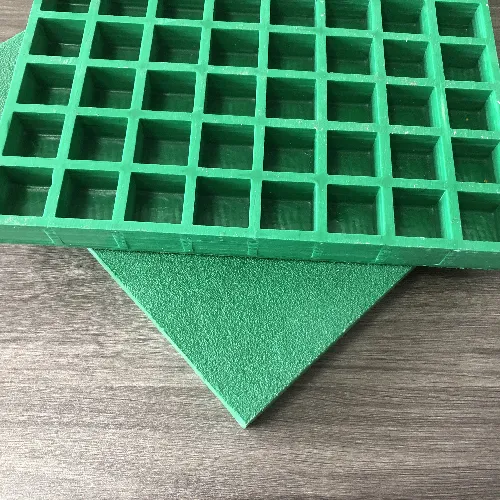

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024